Shower Caddy Factory Development: Rising Interest in Lightweight and Anti-Rust Materials

Innovation within a Shower Caddy Factory is often propelled by clear market needs, and two of the most prominent drivers today are the demand for lighter products and more reliable corrosion resistance. These are not fleeting trends but responses to practical challenges: the growth of adhesive-based installation methods requires manageable weight, and the desire for long-lasting performance in wet environments necessitates advanced material science. Developing solutions that address both areas simultaneously represents a meaningful step forward in product development.

Advancements in Lightweight Construction

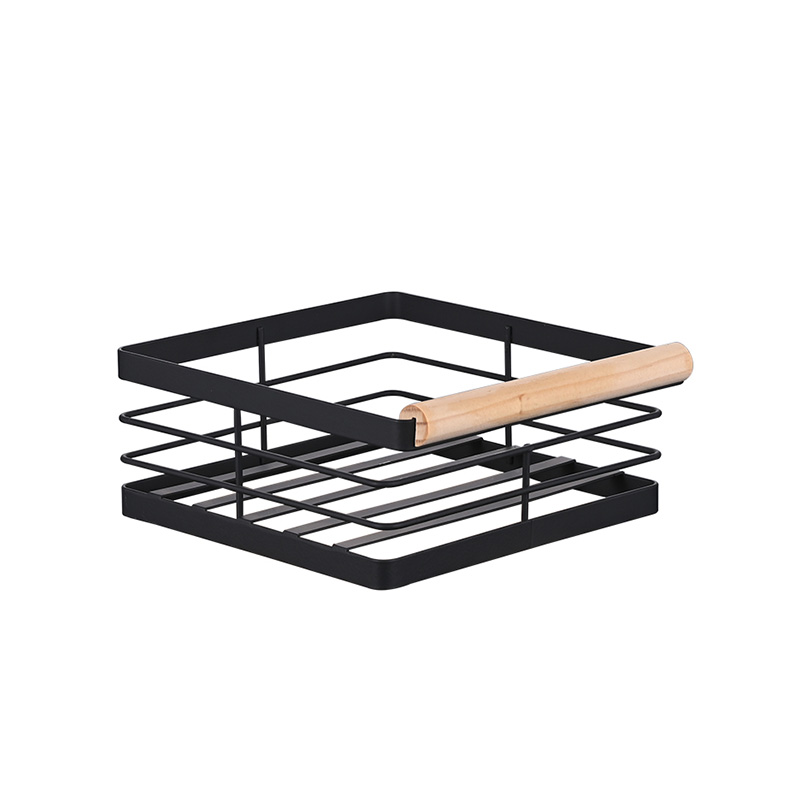

Reducing weight without sacrificing strength is a key engineering focus. This has led to a more common use of aluminum alloys, which offer a favorable strength-to-weight ratio and can be treated with finishes that provide color and additional surface hardness. Simultaneously, progress in polymer technology has resulted in compounds that are both light and capable of withstanding impact and exposure to heat. Beyond material substitution, strategic design plays a major role. Techniques such as creating reinforced rib structures in plastic or employing strategic open frameworks in metal designs remove excess material where it is not needed for structural support. This approach to design ensures the product remains easy to handle and install while maintaining its required load-bearing capacity.

Pursuing Enhanced Corrosion Resistance

The battle against rust and tarnish is fought at the molecular level through both material selection and surface technology. While certain grades of stainless steel provide a solid foundation, the application environment often calls for extra protection. This has increased the adoption of physical vapor deposition (PVD) coating processes. This method creates a thin, dense, and consistent layer on the metal surface that is effective at blocking moisture and is less prone to wear than some traditional platings. For applications where any metal corrosion is a concern, the use of solid, high-quality polymers presents a fundamentally different approach, eliminating the oxidation process and simplifying maintenance.

Integrating Weight and Resilience in Design

The true challenge and opportunity lie in integrating these two properties into a single, coherent product. A practical development path might involve a structure primarily built from a lightweight aluminum frame, with only the most critical load-bearing or high-wear components, such as joints or hooks, made from a specially treated steel. This hybrid approach allows the product to benefit from the primary characteristics of different materials. The development process involves testing these combinations under realistic conditions—assessing not just if they hold weight, but how they fare under cyclical humidity, exposure to cleaning agents, and the stress of installation.

The Practical Implications for Buyers

The shift toward these material developments carries clear benefits for the trade. Lightweight products can contribute to reduced shipping costs, an important factor for bulk international orders. For the end-user, a lighter caddy is simpler and safer to install, particularly when using non-permanent mounting methods. Improved anti-rust characteristics directly translate to product longevity and customer satisfaction, reducing the likelihood of premature failure and associated returns. For a factory, focusing on these areas is a direct response to market demand for convenience and durability. It reflects a commitment to evolving manufacturing techniques and material applications to build products that are suited for contemporary living, meeting practical needs while maintaining a standard of quality that supports brand integrity over time.

-

Feedback

English

English 中文简体

中文简体 русский

русский Español

Español