Shower Caddy Factory Analysis: Installation Methods That Consumers Prefer Today

The moment of installation is a critical touchpoint in the lifecycle of a shower caddy, often determining the user's initial perception and long-term satisfaction. A Shower Caddy Factory must, therefore, analyze and respond to clear consumer preferences for methods that balance security with simplicity. The ideal is a process that feels straightforward, inspires confidence in the product's stability, and respects the integrity of the bathroom walls. Preferences have crystallized around a few key methods, each with its own set of considerations that influence design and manufacturing choices.

The Appeal of Non-Invasive Solutions

Methods that require no drilling are highly valued for their convenience and versatility. Adhesive-based mounts, which use strong, waterproof tapes or pads, allow for secure placement on smooth, clean tiles and can be surprisingly resilient when applied correctly. Vacuum suction cups offer a removable option, appealing to those in temporary living situations. The manufacturing focus for these types is on the quality and formulation of the adhesive or the design of the suction mechanism and its release valve. Consistency in these components is vital, as performance depends heavily on providing a reliable bond with the wall surface. Packaging must include clear surface preparation instructions to ensure successful application.

The Reliability of Permanent Mounting

For a sense of security and for holding substantial weight, permanent screw-in mounting remains a trusted method. Consumers who own their homes or prioritize absolute stability often prefer this option. The manufacturing support for this method involves providing accurately sized hardware suitable for tile or drywall, and clear templates or guides to assist with level and balanced placement. Thoughtful design can also hide mounting points or incorporate them into the product's aesthetic. While the installation requires more effort and tools, the perceived payoff is a permanent, wobble-free fixture that anchors the bathroom's organization.

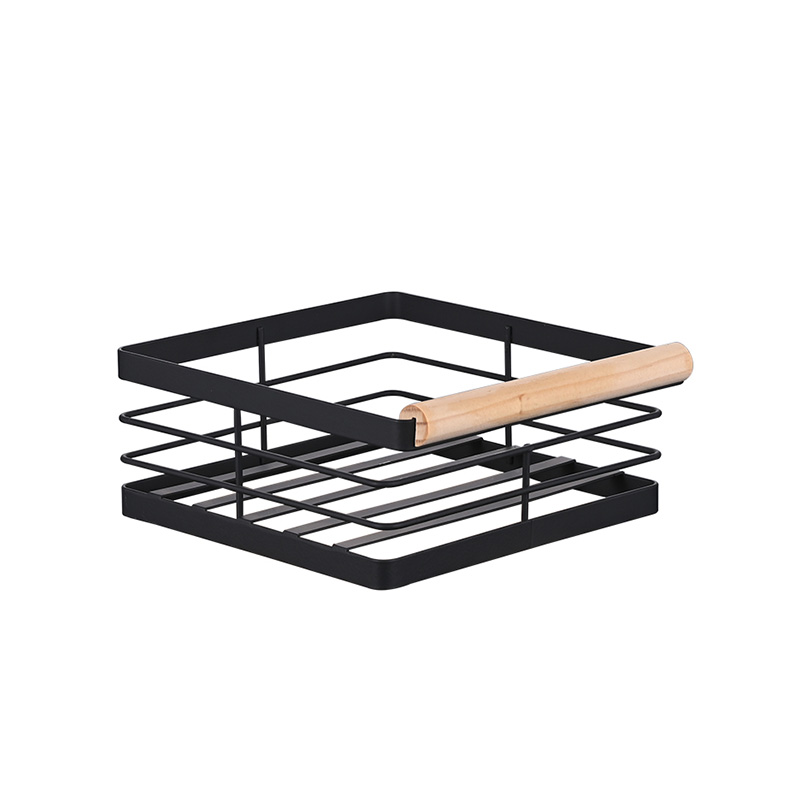

Pressure-Based and Freestanding Alternatives

Tension rod caddies, which use a spring-loaded pole wedged between two walls or from floor to ceiling, offer a distinct alternative that requires neither adhesion nor drilling. Their success depends on the precise engineering of the tension mechanism and the use of non-slip end caps that protect surfaces and prevent slippage. Similarly, freestanding floor caddies provide complete installation flexibility, moving storage needs around the bathroom as required. These options highlight that installation preference is not just about the wall interface but about providing choices that suit different spatial layouts and user capabilities.

Designing for a Confident Installation Experience

Beyond providing hardware, a forward-thinking approach involves designing the entire installation experience. This can include integrating features like built-in spirit levels into the caddy frame, using packaging that clearly organizes all components, and providing visual instructions that are easy to follow without extensive text. The goal is to minimize uncertainty and frustration for the user. For a factory, this means viewing installation not as an afterthought but as a phase of product use that is engineered alongside the caddy itself. Components are selected for their performance, and instructions are developed for clarity.

Meeting Varied Needs with Thoughtful Options

There is no single installation method that suits every consumer. Preferences are shaped by bathroom layout, wall material, tenure in the home, and personal comfort with tools. Therefore, a comprehensive approach involves offering a range of products that employ different installation techniques. More importantly, it involves refining each method to be as reliable and user-friendly as possible within its category. By doing so, a manufacturer ensures that its products are accessible to a wide audience. It allows buyers to select products that align with their customers' specific circumstances, reducing barriers to purchase and enhancing the overall perception of the brand as one that provides thoughtful, considerate solutions for real-world living spaces.

-

Feedback

English

English 中文简体

中文简体 русский

русский Español

Español