Shower Caddy Factory Insights: What Buyards Prioritize in Material and Durability

Consumers continue to seek bathroom storage products that balance reliability, practicality, and long-term value. As interest in well-constructed shower accessories increases, discussions around material selection and durability have become central topics within the industry. A growing number of buyers now evaluate products with closer attention to how well they withstand moisture, daily use, and environmental exposure. Against this backdrop, a Shower Caddy Factory must consider how materials, finishes, and construction methods align with modern expectations.

Decoding Material Choices: More Than Meets the Eye

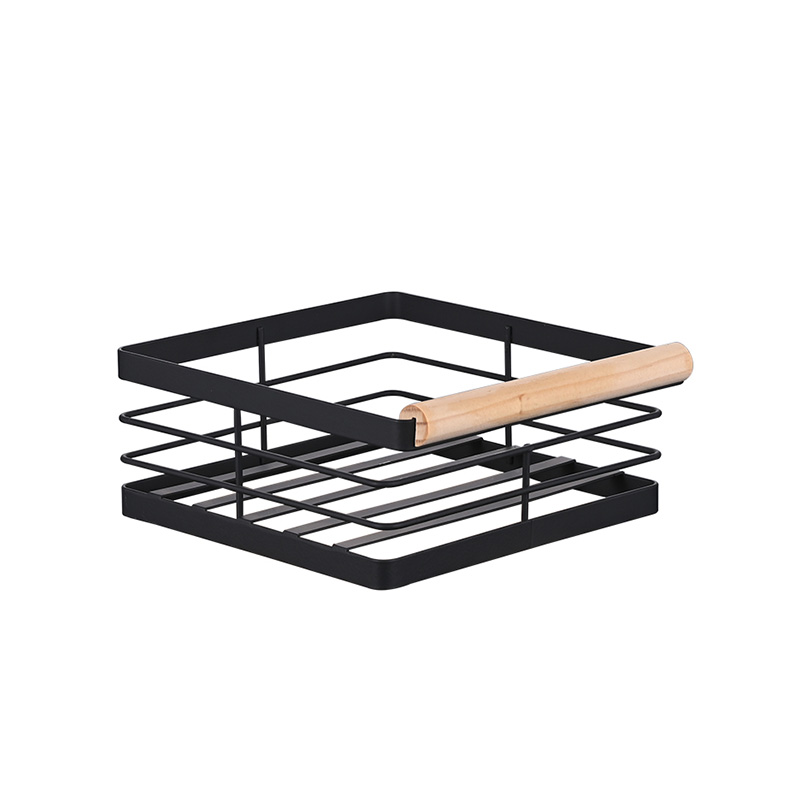

The term "stainless steel" is common, but it represents a spectrum of quality. The differentiation between grades like 304 and 201 is significant, hinging on their respective resistance to corrosion. Environments with constant moisture and varying water qualities demand materials that can resist tarnishing and rust. Beyond metal, engineered polymers offer distinct advantages, including resistance to impact and a capacity for versatile color integration. Materials such as bamboo present an alternative, appealing to a specific market segment looking for naturally derived options. Each material carries its own set of characteristics regarding weight, feel, and environmental interaction, making the choice a strategic one based on the intended use and market positioning.

Engineering for Endurance: Where Durability is Built

Durability is not a coincidence; it is a result of deliberate design and process control. It begins with structural integrity—how the weight is distributed, the way brackets are reinforced, and the overall stability of the caddy when fully loaded. The journey continues with surface treatment. The process of applying protective coatings, whether through electroplating or advanced powder coating, adds a critical barrier against moisture and oxidation. The quality of these finishes determines how well the product maintains its appearance. Furthermore, attention to granular details defines a robust product. This includes the smoothness of welded joints to prevent water traps, the secure fastening of all components, and the finish on edges and corners. These elements collectively prevent common failure points like chipping, loosening, or structural bending.

Aligning Solutions with Application

The practical approach for a Shower Caddy Factory is to align material and construction choices with the product's final application. For settings demanding a balance of strength and corrosion resistance, such as coastal residences or busy gyms, certain material grades and protective treatments are a necessary focus. For everyday household use where weight and cost are considerations, durable polymers or thoughtfully designed steel can offer reliable performance. The goal is to provide a range of solutions that match varying needs without compromising on core build quality. This involves transparent communication about the properties and appropriate use cases for different product lines, enabling buyers to make informed decisions that suit their specific market demands.

Material and durability considerations now shape how buyers evaluate shower caddies for their homes. From corrosion resistance to frame strength and long-term stability, users pay close attention to how well each product performs in the demanding environment of a bathroom. With consumer expectations continuing to evolve, factories face increasing motivation to adopt thoughtful material strategies and manufacturing improvements. These adjustments not only support long-lasting performance but also contribute to user confidence in everyday bathroom use can quickly diminish user satisfaction.

-

Feedback

English

English 中文简体

中文简体 русский

русский Español

Español